New Inventory Daily!

Please call for the latest closeouts and specials.

New Inventory Daily!

Please call for the latest closeouts and specials.

The main component of every warehouse system. It can be used as a stand-alone for pallet storage or as part of complex engineered systems for Carton Flow or Pallet Flow modules.

Designed to manage loads of varying length and proportion. They can be completely accessible from the front without any of the horizontal restrictions of traditional pallet racks. Without front column obstruction, the entire length of the rack may be used for storage. For added flexibility, loads of differing lengths may be stored on the same rack and even at the same level.

A double-sided rack can stand alone with arms on both sides.

The single-sided rack has arms on one side only for access to only one side.

Choose from Straight Arms or Inclined Arms with or without a lip at the end.

Straight Arms are great for storing materials that will not roll, such as wood, steel tube stock or other long square material. Straight arms have a minimum pitch of 3/8” per foot to compensate for deflection.

Inclined Arms are great for storing materials that will roll, such as metal or PVC pipes and other long round material. Inclined arms have a pitch of 20 degrees and are often tapered.

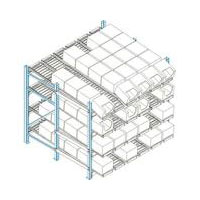

A form of shelving that uses gravity-feed rollers. Racks are a rear load design. Each unit consists of one or more inclined roller runways. Merchandise is loaded in the rear of each runway. As an item is removed from the front, the item directly behind it slides forward in place of the previous

Carton Flow systems for every size warehouse and every price range. All systems are gravity-driven and perfect for applications with numerous SKUs. Stock presents on a First-In/First-Out basis, which ensures inventory rotation. Separating the loading aisle from the retrieval aisle allows pickers to operate more efficiently. Carton Flow, with its tilted shelves which improve visibility and order accuracy, is the perfect answer for split case or piece picking.

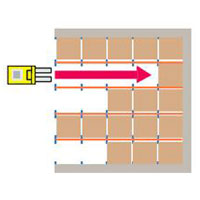

Drive In Racking is the ultimate in high-density storage. No other form provides more storage capacity per square foot of room than drive-in. A viable alternative to expanding one’s facility, drive-in provides a very low cost yet efficient means of high volume storage.

Drive In – Last in First Out (LIFO)

Material is both stored and retrieved from the same side (entry point) in several aisles. For this reason, the first material put in this system is the last to come out. This works well where shelf life is at a minimum or not a major concern. This system also works well in cold storage environments or warehouse freezers.

Offers greater selectivity with the same storage density as drive-in and drive-thru rack. As a new load is placed into a lane, it “pushes back” the first load and all those behind. When the load in front is picked, all the loads in the lane move forward one position.

Push Back rack systems are available in structural or roll-formed frames. The systems work by placing pallet loads on a series of nesting carts fed forward by gravity on rigid structural steel rails. As a pallet is loaded from the front, it pushes the pallet behind it back one position. When unloading, the front pallet is removed and the rear pallets automatically come forward to the front picking position. This allows for easily accessible Last-In-First-Out (LIFO) inventory management. Operators can store product from 2-5 pallets deep, with front-only loading from a single aisle.

Wire decking is a great add-on for your pallet rack. It is economical for new installations and for upgrading your current rack system. Decking provides greater structural strength than other materials. Tough and durable wire construction with underlying metal supports. It offers easy visibility for rack content inspections and meets fire safety codes. With Decking, you eliminate dust and debris build-up and improve air circulation. It meets ANSI MH-26.2 standards. Wire rack decking is constructed from heavy-duty 4-gauge wire.

Pallet Rack

Cantilever Rack: Double-Sided Rack

Cantilever Rack: Single-Sided Rack

Straight Arms

Inclined Arms

Carton Flow Rack

Drive-In Rack

Push Back Rack

Wire Deck

If you are looking for other equipment or you have equipment to sell please contact us.